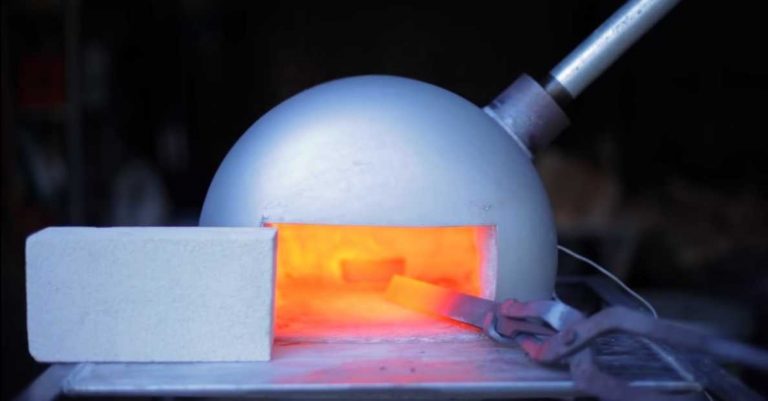

A forge is a fireplace, and we use it for heating metals. The workplace with such a fireside is also a forge. While making a homemade forge, you have two major fuel options: coal and gas. A coal forge is a more traditional and old design, but a gas forge is small, simple, and easy to control.

Gas Forge: What It Is?

A gas forge generally uses propane or natural gas as the fuel. Still, it is the most convenient gas forge. However, it runs at a bit over 2000 degrees Fahrenheit, which is certainly enough to do common forging. Generally, it has effective design uses a cylinder-shaped forge chamber and also a burner tube mounted at a right angle to the body.

Though, the propane forge is essentially an insulated box of various sizes and shapes. But it has one or more burners in the top or the side. Generally, the burners can be atmospheric or have a power-driven blower attached to them. Still, the chamber holds the heat to heat the bar, and the burner provides the heat. But, you can do only what you can fit in a propane gas forge.

Still, you can use a high-temperature ceramic fiber as the insulation in a blacksmith gas forge. They are such as Kaowool, Durablanket, or Fiberfax. However, this insulation lets the high temperature inside the gas forge but inhibits the outer shell from declining. Moreover, you may also use hard or soft firebrick to hold the heat in the forge chamber.

The main benefit of a gas forge is, it is easy to use for a beginner, in particular. It is easy to run compared to coal forges, and yet the fire produced is clean and consistent. You cannot reshape the fire to accommodate big or extraordinarily shaped pieces because they are less versatile. But they are easier to make, use, and maintain.

Looking for forge product? Gas forges, nonetheless, offer a more efficient approach to metalworking. You may rely on gas forge because it is easy to setup, and keeps work conditions predictable.

Moreover, the smiths use the forge to heat the metal to make it easier to for many shape by forging or to the point where it is suitable to give different shapes.

How a Gas Forge Work?

A gas forge uses either natural gas or propane as its fuel. Still, it is usually shaped like a cylinder. Moreover, you can use refractory ceramic as a line in its inner walls. You can ignite a fire, while you combine the fuel with the air. Increase the volume of air flowing into the tubular passage going into the fire, so it will make a bigger fire. The gas forge still, stays at full power, sustains a steady heat, and requires little or no cleaning.

Though the traditional blacksmith’s forge has changed and developed more sophisticated over time, but, the basic principles stay untouched. Still, the forge is a mostly designed fireplace where you can regulate the temperature. However, the blacksmith heats the metal to the temperature depending on what he plans to do such as- shaping, annealing, or drawing.

Many modern blacksmiths use gas forges and its fuel is either natural gas or propane. You can provide the gas into the hearth, which is lined by ceramic refractory materials. When mixing it with the air, then ignite. By adjusting the gas pressure into the hearth, still, one can regulate the varying temperature. However, gas forges are easier to use and require less maintenance and cleaning. But, it has advantage, unlike a coal-fired forge. The shape of the fire is fixed, and so, you cannot change it to suit the shape and size of the metal being heated.

Gas forges come in various forms and sizes. Large enterprises use a massive gas forge, while small businesses would need a smaller one. A lot of people like to use this kind of forge because of its easiness. You will not face any problem running a gas forge, and nonetheless, you are guaranteed a steady and fresh fire.

How to Build a Gas Forge?

In the workshop still, the metal is only as good as its temper. A forge, however, permits the craftsman to change the metal properties like its hardness, shape, and strength according to a project dictates. However, various ways to complete for such a job, yet, a propane forge is Hygienic for the DIYer.

Planning for Your Forge

- Setting the objective: Above all, decide about the end products and the goal of this forge. What you want to make or work with it and additionally, the amount of use of the forge is essential.

- Making a tentative plan: You should resolve on these issues for example burner’s quantity, forge size, usage volume, cost, short-cuts, etc.

- Operating place: Still, it is critical about the place where you will build and operate the forge. Therefore, use it in a well-ventilated area.

- Finalizing the plan: Create a parts list based on forge design. Confirm “designs” also, as to what the forge will be, part by part, and based on size.

- Collecting parts: You can do as you make your way building components. Nevertheless, you can build a gas forge without spending a dollar, but you will need to search for parts.

Constructing the Forge

- Building the forge body: The body and the burners, above all, are two main components of the gas forge. Consequently, you can use any metal container to make the body. But, this body requires to be lined with an insulating layer. Though firebrick is inexpensive but very inefficient, while high-temperature ceramic fiber blanketing is costly, but retains heat very well.

- Setting up the burner: Burner tube mounted at a right angle to the body, certainly it applies heat to the forge.

Testing and Using the Forge

- Trial and using the forge: Soapy water is suitable to check whether the gas line leaks or not with the pressure. Moreover, you can use a medium-sized metal file to see how hot the forge can get and how fast it heats up.

Gas Forge Maintenance and Safety Measure

The fire formedin a gas forge is fresh, and in addition, the operation temperatureremains steady. The gas forge burns gas as the fuel, so there is little or no remnant. A gas forge care only needs occasional cleaning, but the smiths must be sure to ventilate during and after working.

Nonetheless, the option of a gas forge is a great bonus to the modern blacksmith. For those that want a speedy heat source with nominal care, such as hobby blacksmiths, it is perfect. However, many professional blacksmiths make their living with a propane forge and only use a coal forge occasionally.

The size of a propane forge is, in general, small and easily portable. So, many hobby smiths will transfer a propane forge out into the driveway or may use outdoor.

Safety Precaution:

- Use gloves because hot metal is not like hot food. It doesn’t cool down as quickly when in contact with skin.

- Nonetheless, light the forge with a torch, long match, or something that gets your hands away from the opening of the forge door. Thus, do NOT light a burner at the air choke.

- Propane is explosive. So, you could expire if you do not treat it as such.

- However, the leaving gasses of a forge, propane, or coal, are fatal. As a result, one could decease other wise use a well-ventilated working space.

- All the time, use safety glasses during your work. Metal scales, when heated up, may fall off when you work.

- A gas forge stand is decent if it needs to use and move a lot.

- Also, you must need a gas regulator to run this burner.

- You cannot inhale just propane, because it is toxic. Otherwise, you will die.

Where do I find the liner?

If you search “kaowool” and fire clay online, therefore, you will get various resources for it. Kaowool is a fire-resistant insulator, so your forge grips heat. Firebrick is an inferior insulator. So, perfectly, you can use both; the brick for the resilience, and consequently, it is capable of enduring the heat without breaking up. However,the wool, and fire clay for insulation to defend your forge shell.

Can the forge melt down steel?

If it acquires hot enough, consequently, it could probably melt the steel.

Can I use an old water tank to make a forge?

Yes, you can use a tank that is 12 inches in width for the best results. Thus use insulating wool for the best outcome.

Can I fire bricks inside and have a concrete forge outside?

You could use the fire bricks on the inside and but concrete on the outside, yes. So be assured to insulate the concrete well and do not cool it too rapidly after working so it will not crack.

Should I require an inline spark?

No, you do not need it. Though you require an ignition source to start the propane. The fire will reignite once it gets hot enough if it blows out or goes out when you change the flame.

Wrapping Up

Still, the option of a gas forge is a great advantage to the modern blacksmith. For those that want a quick heat source with slight maintenance, such as hobby blacksmiths, it is ideal. The main benefit of a gas forge is, it is easy to use for a beginner, in particular. It is easy to run compared to coal forges, and yet the fire produced is clean and consistent. But they are easier to make, use, and maintain.