A mill is one kind of device that executes to break, crush, grind or cut any solid materials to small pieces. It forces the object with high pressure, and it breaks down to pieces in the ancient era mill used to operate by hand or wind. Then in the middle time mill used to operate by an animal, water, etc.

But now this modern era it is powered by electric supply. Mini mill is essential and helpful for making our work easy. It used in industry, farm, even in the kitchen. In this article, we will emphasize more in the Steel industry.

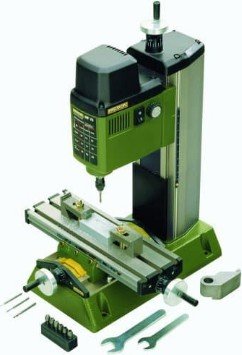

What is a Mini Mill?

In industry there are quite a few mills are used for breaking, melting and burning the materials. The particle of any materials primary processed in mills. Then those are used for further processing. So they are called secondary mill or mini mill. It makes manufacturing work more easy and fast. Mills are used in farm and gardening as well.

Such as sawmill for cutting wood. There is also some mill like handheld mill for spinning wheel. Nowadays we are used to on electric power mill. But there was a time human operate mill by water, wind, animal and hand, etc. lets; the how did these work:

Hand Mill: There is various type of hand mill that used to grind or paste many ingredients. Such as spices! Some have wheel operated by hand to run it.

Wind Mill: Generated by the wind to execute water pump. This type of mill used to seen many years ago in the field or farm. Now it is transformed into wind turbines to product current.

Water Mill: It uses hydropower to generate the machine. With the process hammering, rolling or grinding any materials are completed.

Horse Mill: Horse powered mill operated by horse to grind or water pump. Other animals also are used as a cow for mashing seeds to produce oil.

Electric Mill: Now the people use electric power mill for the fastest result. They have made different size mill according to their need. Then generated it with electricity and those are utilizing in the different field.Their other mills as well ship mill, roller mill, etc. today’s modern mill that we see around us the concept is taken from these ancient structures.

You may also like: best sliding table saw

What is a Steel Mill

If we defined it simply, steel is a mill that used in the steel industry or used in the procedure of manufacturing steel. But it is a secondary mill that prepares materials for steel production. There are lots of steps to develop steel. That does not work in just one machine.

So, the raw materials are processed in a different machine and proceed to the final stages. The steps are included:

- Liquiding iron.

- Liquiding steel.

- Induration of the steel (casting).

- Roughing or billet rolling (minimizing the block size).

- Final shaping (product rolling).

The making of steel many materials are used as raw and goes through several stages. The main material is iron ore. That has to make a liquid with some others element. That completed on blast furnace one kind of machine to use solid melting ingredients.

Then it goes to some other process and different machine. Such as oxygen furnace. Previous Bessemer process was simplified, but the new idea was taken from this machine.

Read more : best milling machine buying guide

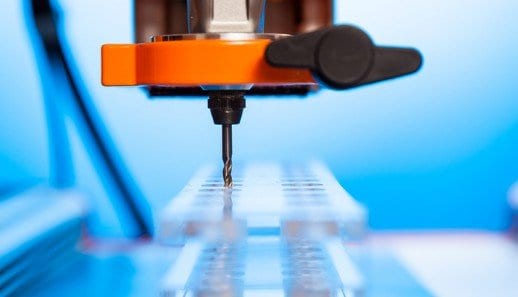

Why The Mills Are Used In Industrial Work

There was the time people had to do single things by hand. It usually takes quite a long time for working with own. Resulting in lateness and poor consequences. When the mill comes with electric power, it discovers the industrial revolution. Because of electric mill able to provide the best result in the shortest time.

It saves time and earns a lot of money. Where 100 people are needed to finish work, there only one machine can do it within one hour. But there is also another reason behind it. Let’s look at that:

Safes Time

In the workplace, everything needs to be completed timely. Time and money are related to each other. If it takes the entire day to produce any materials by a thousand workers, the electric mill may take a half day. That’s how the industries are making money. Every industry makes its mills with engineer according to product type.

Quick Production

The electric mill can deliver the products quickly and in a short time. Far better than simple workers. Even it save cost as well. One machine can run for years. If it is sold, it has priced in the market. But in the same place, there might be hired several workers and paid a lot of money.

Reduce Cost

The worker is provided with other financial support as well as daily salary. And, it increases yearly. So, an industrial company cannot make a profit only with workers.

Wheres, machinery that produces the product quickly can reduce company cost. As it is discussed earlier, a thousand works execute the works in the entire day; one machine can do it in half day.

Defectless Product

It may appear any defect or fault for human making products. Even the result might not be satisfactory. But producing on machinery may give the perfect and defectless product. Because there are different machines are used in the various section. Every machine has its measurement so it can not do anything by its own choices.

Risk Work

There are some production and industrial work that human has life risk. There should be used machinery for safety purpose. Such as steel industry, Mining, etc. anyone can lose their life by working that risk factory. So, there are used machinery for production.

Wrapping Up

Hopefully, our reader will understand now what is a mini mill and secondary mill. These are utilized for farming, gardening, producing food and business purpose. These are essential for our daily life, working life and personal life.

These mills have brought comfortness and offer a smooth life.